Technologies

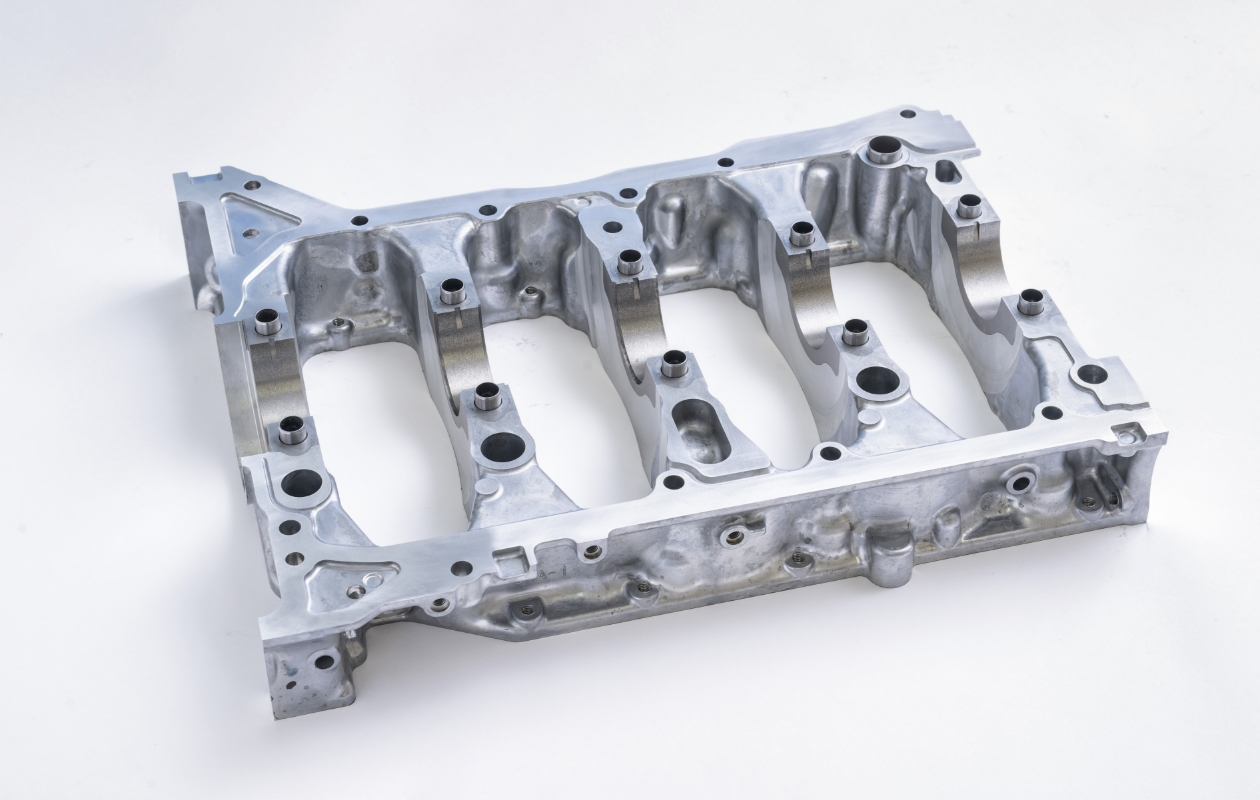

Gravity Die Casting

Gravity Die Casting is a casting process in which molten metal (molten aluminum alloy) is poured by gravity into a mold under atmospheric pressure to make products.

Unlike sand molds, molds can be used repeatedly, enabling continuous casting.

In addition, the use of shell cores improves the degree of freedom of shape and enables the molding of complex products.

These products are characterized by strong parts and complex shapes.

Even the shape with many arm sections provides good hot-water circulation.

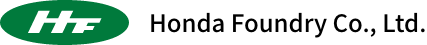

Low Pressure Die Casting

Low Pressure Die Casting is a casting process in which pressure higher than atmospheric pressure is applied to the surface of molten aluminum in a sealed holding chamber to push molten aluminum up through a stalk inserted into the molten metal and pour it into a mold.

By using shell cores, this process can also form hollow castings, which are characterized by their high quality.

These products are large in size and make extensive use of ribbed shapes.

By using multiple shell cores, cooling and air circuits are molded inside the casting.

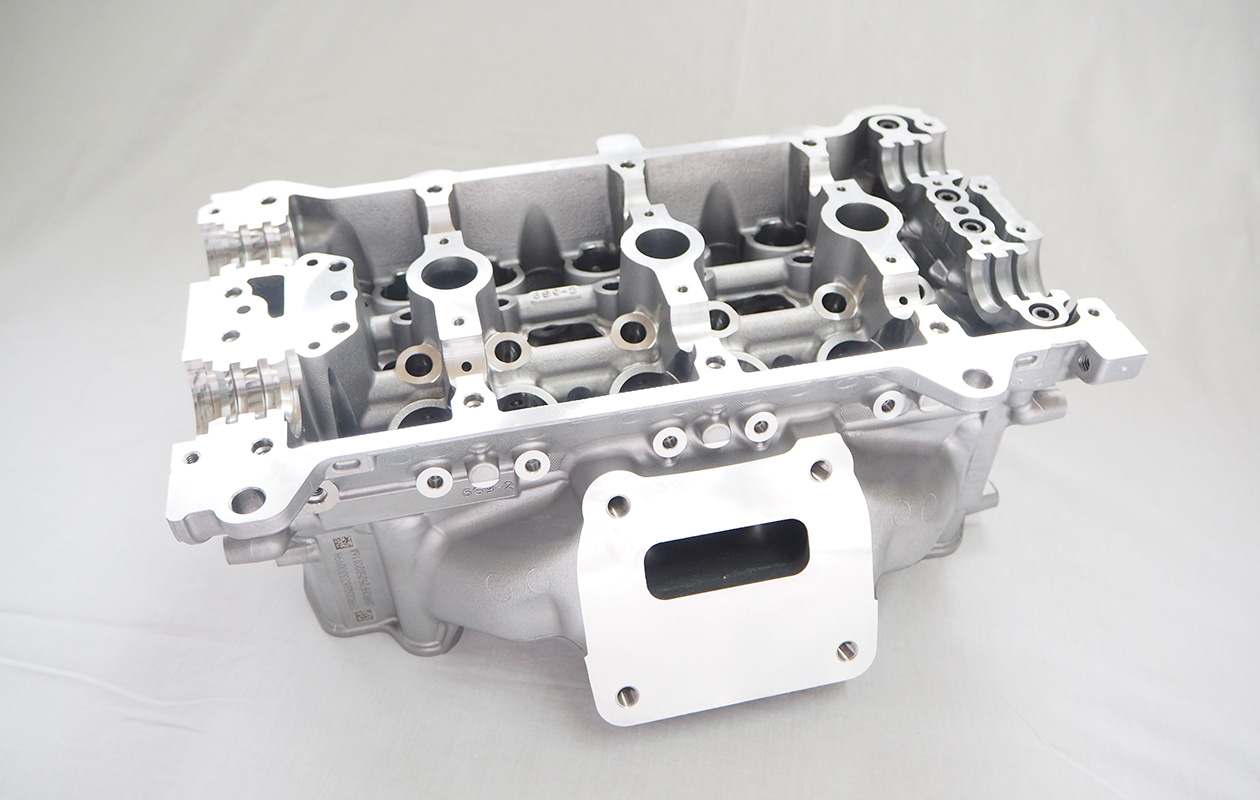

High Pressure Die Casting

High Pressure Die Casting is a casting process in which molten metal is poured into molds at high speed and high pressure to make products.

The casting cycle is short, and the thickness of the product can be reduced, contributing to weight reduction of the product.

This product is thin-walled and mass-produced.

Iron journals are cast and molded into the shaft bearing surface.

HFEMDC®

Honda Foundry Electro Magnetic Pump Pouring Die Casting

Honda Foundry Electro Magnetic Pump Pouring Die Casting (HFEMDC®) is our proprietary casting technology that uses an electromagnetic induction pump to inject molten aluminum alloy into a mold to help manufacture products.

The Precise control of the electromagnetic induction pumps has enabled us to achieve the ideal metal flow, making it possible to mold high-quality product materials using only powder mold release agents without the conventional mold coating agents.

This product is characterized by complex rib structures of various sizes and varying wall thickness.

By using this sophisticated molding method we made it possible to bring the desings to life.

Contact Us

Contact us for more information about our company, questions, or for a quote.

To Contact Page