Mold Coating & Release

Advanced Technology Feedback Opens a New Era in Light Metal Casting

Our product line is not limited to the automotive industry. Demand for aluminum casting products is increasing in industries that are under pressure to reduce the weight, precision, and cost of product parts.

In these times, we have further enhanced our own research and development department.

In addition to advancing the cutting-edge technologies we have cultivated up to now, we also strive to research and develop new technologies and materials, and feed them back into new products. Our product lineup is capable of responding immediately to various needs.

In addition, we accept orders for everything from mold making to product manufacturing upon customer request, providing strong support in new areas.

LNO(Mold release agent for aluminum casting)

Our mold release agent, which is specially designed for aluminum casting products, is easy to use and has a long service life.

It significantly reduces aluminum adhesion to molds, reduces man-hours required for mold maintenance, improves production efficiency, and extends the life of important molds.

Liquid color: White / Volume: 5 kg / Price: Open

Quolities

- Eliminates galling and seizure in areas where there is little relief, and in hot water channels and openings, which are always under high temperatures.

- Can be applied with a brush or a brush, enabling application to mold details.

- Low viscosity allows for easy mixing of the agent even after long-term storage.

- Adsorbs to all types of molds while not adhering to aluminum.

※Dilute with 1 to 5 times kerosene depending on the application.

Purpose

- Casting molds: Repairing of galling and areas with significant aluminum adhesion in low-pressure and gravity casting molds. Repair of areas with severe deterioration of the base coating material.

- Incidental equipment: Direct lining of hot water ladles for die casting, hot water tribes, inside ingot cases, etc.

How to use

- Preheat the mold to be coated to 70-100°C and apply the blended “LNO”.

- After the mold coating is completed (assuming the mold temperature is 100°C), apply directly to the necessary areas with a brush or brush, and adjust the film thickness to the desired level by blowing air to produce a smooth surface.

- When applying to ancillary equipment, use shot blasting, etc. to completely remove oil, grease, dust, aluminum adhesion, etc., and preheat the equipment to around 100°C before direct lining.

Caution

- Wear a dust mask, eye protection glasses, and gloves when using the product.

- n case of contact with skin or clothing, wash immediately with soap and water. If it gets into eyes, mouth, etc., wash thoroughly with tap water and consult a physician. If it gets into eyes, mouth, etc., wash thoroughly with tap water and consult a physician. If it gets into eyes, mouth, etc., wash thoroughly with tap water and consult a physician.

- For long-term storage, wipe off all residues around the lid and store in an airtight container in a cool, dark place. Wipe off any deposits around the lid and store in an airtight container in a cool, dark place.

- The applied part of the product may shine on some surfaces of the product, so be careful when using the product on exterior parts. Please be careful when using this product on exterior parts, etc.

- Expiration date: 1 year from the date of manufacture.

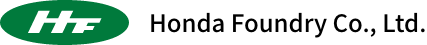

LNO-HG(Mold release agent for aluminum casting)

LNO has been upgraded to a new level, with freely selectable installation temperatures, making it even easier to use.

Liquid color: Gray / Volume: 5 kg / Price: Open

Quolities

- Can be applied at 300-400°C and can be applied to molds during casting.

- The coating does not drip and can be applied at room temperature.

- The addition of graphite further strengthens the coating film.

- Formed with NO binder, there is almost no precipitation of the agent.

- Easy to handle as it does not require blending and can be used undiluted.

Purpose

- Casting molds: Repairing of galling and areas with significant aluminum adhesion in low-pressure and gravity casting molds.

- Repair of areas with severely deteriorated base coatings.

- Furthermore, it can be applied to the parting surface to prevent the occurrence of casting burrs.

- Incidental equipment: Direct lining of hot-water ladles for die casting, hot-water tribes, inside ingot casing, etc.

How to use

- Apply this product to the necessary areas of the molds to which the coating agent has been applied, and dry the oil and fat in a drying oven or over an open flame before casting.

-

When applying to ancillary equipment, use shot blasting, etc. to completely remove oil, grease, dust, aluminum adhesion, etc., before direct lining.

(Preheating the object to be coated will extend the material and increase the area to be coated, making the work easier.) - Preheating the object to be coated may cause combustion gases to be generated, so be sure to dry thoroughly before application.

Caution

- Wear a dust mask, eye protection glasses, and gloves when using the product.

- If the product gets on skin or clothing, wash immediately with soap and water. In case of contact with eyes or mouth, rinse thoroughly with tap water and consult a physician.

- For long-term storage, wipe off all residues around the lid and store in an airtight container in a cool, dark place.

- The applied portion of the product may shine on some surfaces of the product, so be careful when using the product on exterior parts.

- Expiration date: 1 year from the date of manufacture.

LNO-MG(Mold release agent for aluminum casting)

Upgraded version of LNO (mold release agent for aluminum casting)! Quick-drying and greatly reduces the amount of combustion gas!

Liquid color: Gray / Volume: 5 kg / Price: Open

Quolities

- It has improved the evaporability of oil and fat content compared to the conventional LNO-HG, enabling products to flow as good products immediately after application to molds during casting. (Our company’s comparison)

- Even under the condition of application during casting, the effect of the coating agent does not deteriorate. (our comparison)

Purpose

- Continuous repair of galling during casting operations, areas with significant aluminum adhesion, and areas with severe deterioration of the base coating material. Continuous repair of areas where galling and aluminum adhesion during casting operations and deterioration of the base coating material are severe.

- Lining repair of areas where casting burrs occur.

- Lining of protective agents for die casting ladles, hot water tubes, etc. in continuous operation. Lining of protective agent for die casting ladles, hot water tribes, etc. in continuous operation.

How to use

- Apply this product to the necessary parts of the molds to which the coating agent has been applied, and dry the oil and grease in a drying oven or over an open flame before casting.

-

When applying to ancillary equipment, use shot blasting, etc. to completely remove oil, grease, dust, aluminum adhesion, etc., and then directly line the equipment.

(Preheating the object to be coated will extend the material and increase the area to be coated, making the work easier.)

Caution

- Wear a dust mask, eye protection glasses, and gloves when using the product.

- If the product gets on skin or clothing, wash immediately with soap and water. In case of contact with eyes or mouth, rinse thoroughly with tap water and consult a physician.

- For long-term storage, wipe off all residues around the lid and store in an airtight container in a cool, dark place.

- The applied portion of the product may shine on some surfaces of the product, so be careful when using the product on exterior parts.

- Expiration date: 1 year from the date of manufacture.

RIO-A(Mold coating agent for aluminum casting)

Mold coatings for low-pressure casting and gravity casting for pouring, push-boards, runner sections, etc.

Heat resistance temperature: 1200°C.

Liquid color: pink / Contents: 5kg, 10kg / Price: open

Quolities

- It has excellent water resistance and absorbs almost no moisture from the air.

- It can be maintained (repaired) at the same time with the same life as that of the product part.

- Heat retention is approximately 2 times higher than that of the product part (cooling rate 0.57 → 0.30°C/sec), making it easier to obtain directional solidification.

Purpose

- Molds for the design of the gate, push-boards, runner sections, etc., for low-pressure and gravity casting. Mold coatings for low-pressure and gravity casting.

- Mold coatings for brush application to areas where solidification needs to be extremely delayed.

How to use

- Dilute the undiluted solution with tap water at a ratio of 2 parts undiluted to 1 part tap water (by weight), and agitate further.

- Remove all dust, oil, and oxide film from the surface to be coated with the product, and apply the product in layers with a brush while crushing the foam.

-

Keep the mold temperature from 190°C to 150°C or more immediately before application. The coating thickness = 0.5 to 0.7 mm (our actual results).

(The best coating strength can be obtained when applied uniformly at a film thickness of 0.5 to 0.7 mm (our actual results).

※Please mix the material thoroughly to maximize the performance of this material.

Caution

- Wear a dust mask, eye protection glasses, and gloves when using the product.

- If the product gets on skin or clothing, wash immediately with soap and water. In case of contact with eyes or mouth, rinse thoroughly with tap water and consult a physician.

- For long-term storage, wipe off all residues around the lid and store in an airtight container in a cool, dark place.

- The applied portion of the product may shine on some surfaces of the product, so be careful when using the product on exterior parts.

- Expiration date: 1 year from the date of manufacture.

HK109-19A(Mold coating agent for aluminum casting)

Mold coating agent for low gravity casting. Heat resistant up to 1200 degrees Celsius.

Liquid color: Pink / Contents: 5 kg, polyethylene container / Price: Open

Quolities

- It has excellent water resistance and absorbs little moisture from the air.

- Compared to our former coating agent (DH1), it is superior in strength and durability. No peeling even after 2,000 shots or more in the gravity casting process. (Our actual results)

- Compared to HK109-19Z, the surface roughness of the coating film is rougher, and molten metal can flow around it more easily.

Purpose

- Mold coatings for gravity casting.

- It is suitable for molding thin-walled/lightweight castings with heat resistance and flowability. It is suitable for thin-walled/lightweight castings.

- It can be used with various aluminum alloys and is also compatible with high-silicon alloys. It can be used with various aluminum alloys and is also compatible with high-silicon alloys.

How to use

- Dilute the undiluted solution with tap water 1:1 (ratio by weight), Mix the undiluted solution thoroughly and dilute it further.

- Preheat the mold to be applied at around 250°C, and completely remove dust, oil, and oxide film by shot plastering, etc. Preheat the mold to be applied at around 250°C, and completely remove dust, oil, and oxide film by shot plasting, etc.

- Keep the temperature of the mold at 230℃ immediately before application, and apply evenly to the mold with a spray gun. Apply evenly to the mold with a spray gun. (The temperature of about 190°C is desirable as the end temperature of the coating.)

※Please mix the material thoroughly to maximize the performance of this material.

Caution

- Wear a dust mask, eye protection glasses, and gloves when using the product.

- If the product gets on skin or clothing, wash it off immediately with soap and water. If it gets into eyes, mouth, etc., wash thoroughly with tap water and consult a physician. If it gets into eyes or mouth, rinse thoroughly with tap water and consult a physician.

- For long-term storage, wipe off any deposits around the lid completely and store in a cool, dark, airtight container. Store in an airtight container in a cool, dark place.

- Expiration date: 1 year from the date of manufacture.

HK109-19Z(Mold coating agent for aluminum casting)

Mold coating agent for gravity casting. Heat resistance temperature: 1200°C.

Liquid color: Pink / Contents: 5 kg, polyethylene container / Price: Open

Quolities

- Excellent water resistance, with almost no absorption of moisture from the air.

- Compared with our former coating agent (DH1), it has superior strength and durability. Compared to our old coating agent (DH1), it has higher strength and durability. No peeling even after 2,000 shots or more in the gravity casting process. (Our actual results)

- Compared to HK109-19A, the surface roughness of the coating film is finer, making it suitable for cast product surfaces (design surfaces). Suitable for cast product surfaces (design surfaces) with finer surface roughness than HK109-19A.

Purpose

- Mold coatings for gravity casting.

- It is suitable for molding thin-walled/lightweight castings with heat resistance and flowability. It can be used with various aluminum alloys.

- It can be used with various aluminum alloys and is also compatible with high-silicon alloys. It can be used with various aluminum alloys and is also compatible with high-silicon alloys.

How to use

- Dilute the undiluted solution with tap water 1:1 (ratio by weight), Mix the undiluted solution thoroughly and dilute it further.

- Preheat the mold to be applied at around 250°C, and completely remove dust, oil, and oxide film by shot plastering, etc. Preheat the mold to be applied at around 250°C, and completely remove dust, oil, and oxide film by shot plasting, etc.

- Keep the temperature of the mold at 230℃ immediately before application, and apply evenly to the mold with a spray gun. Apply evenly to the mold with a spray gun. (The temperature of about 190°C is desirable as the end temperature of the coating.)

※Please mix the material thoroughly to maximize the performance of this material.

Caution

- Wear a dust mask, eye protection glasses, and gloves when using the product.

- If the product gets on skin or clothing, wash it off immediately with soap and water. If it gets into eyes, mouth, etc., wash thoroughly with tap water and consult a physician. If it gets into eyes or mouth, rinse thoroughly with tap water and consult a physician.

- For long-term storage, wipe off any deposits around the lid completely and store in a cool, dark, airtight container. Store in an airtight container in a cool, dark place.

- Expiration date: 1 year from the date of manufacture.

Contact Us

Contact us for more information about our company, questions, or for a quote.

To Contact Page